• Alfalfa yield and quality should be balanced with stand longevity.

• Key management practices include fertilization, pest management, harvest scheduling, and storage.

The Yield and Quality Trade-off

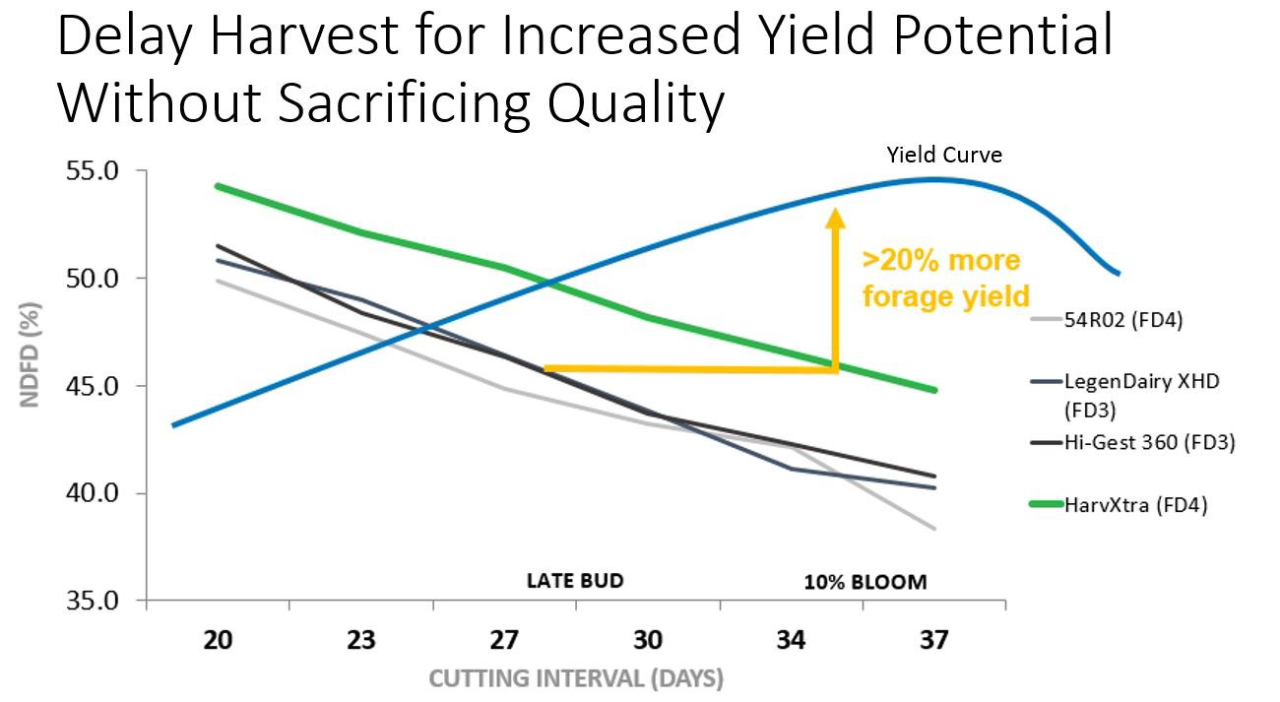

Historically, there has always been a trade-off between quality and quantity with the date of alfalfa harvest. Allowing conventional alfalfa plants to grow beyond the most desirable growth stages generally increases yield potential; however, due to the increase in lignin, overall quality decreases. A reduction in lignin content as the plant ages would increase the digestibility of alfalfa, allow for a longer growing period between cuttings, yield potential and open the harvest window wider to allow for increased flexibility for harvest timing. The advent of HarvXtra® Alfalfa with the Roundup Ready® Technology trait has caused the quality penalty to be reduced as yield increases.1 However, alfalfa without this trait loses quality as the plant continues to grow in an attempt to maximize yield potential. Alfalfa is versatile enough to be used in many types of livestock operations; therefore, management should be focused on the end goal for yield and quality for the type of livestock being fed.

Figure 1. Delayed harvest of HarvXtra® Alfalfa can potentially add yield without sacrificing quality. (Data comes from Forage Genetics International trials comparing HarvXtra® Alfalfa with Roundup Ready® Technology 2017 FD4 commercial varieties to commercial checks. Trials were seeded in 2013 and harvested in 2014, 2015 and 2016 in Boone, IA; Mt. Joy, PA; Nampa, ID; Touchet, WA; and West Salem, WI. Yield increase is directly correlated to the ability to delay harvest.)

Figure 1. Delayed harvest of HarvXtra® Alfalfa can potentially add yield without sacrificing quality. (Data comes from Forage Genetics International trials comparing HarvXtra® Alfalfa with Roundup Ready® Technology 2017 FD4 commercial varieties to commercial checks. Trials were seeded in 2013 and harvested in 2014, 2015 and 2016 in Boone, IA; Mt. Joy, PA; Nampa, ID; Touchet, WA; and West Salem, WI. Yield increase is directly correlated to the ability to delay harvest.)

Fertilization

Soil testing is recommended to ensure that soil pH and fertility are at the ideal levels. A soil pH level of 6.7 to 6.9 should be maintained to maximize yield and quality potential. The key nutrients include nitrogen, phosphorus, potassium, and sulfur. Nitrogen can help increase stand establishment and potential yield in the seeding year. Phosphorus encourages good root growth during stand establishment. Potassium helps to maintain yield potential and stand longevity. Alfalfa has also been shown to be responsive to sulfur. A soil test will not accurately predict sulfur requirements, so a tissue test is recommended. Yield goals should be considered when building a fertility plan. An alfalfa yield of 5 tons/acre can be typical in non-irrigated regions, while over 15 tons/acre can be obtained in irrigated regions.

Pest Management

Using integrated pest management practices for weeds, diseases, and insects can help increase yield and quality. Consult local University Extension specialists on local recommendations for management strategies for specific pests in your area.

Harvest Scheduling and Management

The intensity of cutting management (number of cuttings per year) should be based on the desired quality and life expectancy of the alfalfa stand. Alfalfa producers who want to harvest based on forage quality need to pay close attention to harvesting on time, especially the first cutting. One method to monitor the growth stage of first cutting alfalfa is the PEAQ (predictive equations for alfalfa quality) stick method. The PEAQ stick uses both alfalfa stem height and maturity to predict forage quality. You must be able to distinguish alfalfa growth stages (vegetative, early bud, mid bud, late bud, and full bloom) to accurately assess alfalfa quality.

For dairy production systems, cuttings are usually on a 28 day schedule after the first harvest. In beef systems, cutting is usually delayed until about 10% bloom to maximize yield but maintain a quality suitable for beef production.

Cut height is an additional harvest consideration. The general recommendation is a cut height of 2 to 3 inches, except for the final cutting height, where a 4-inch height is recommended in northern areas to help catch and hold snow. Research has shown that for varieties that do not have the HarvXtra® trait, every 1-inch reduction in cutting height results in a 0.5 ton/acre increase of dry matter over the course of the season. However, quality decreased by about four relative feed value units for each cutting.2

Wider harvest swaths can help speed up drying time, decrease dry matter loss in the field, and result in improved quality. A wider swath can reach 65% moisture in 5 to 8 hours, allowing for haylage harvest the same day. Minimizing wheel tracks can also help educe yield losses for successive cuttings.

Storage

Storing hay inside a building results in minimal dry matter losses of 1 to 5%. Hay in contact with soil and left uncovered in the field can result in a loss of up to 50% dry matter after one year. Even if covered, contact with soil can result in a 15% dry matter loss. Moisture can be kept from wicking from the ground by using plastic wrap, large crushed stone, ties and/or poles, pallets, or tires.2

Sources:

1Combs, D. 2016. Low-lignin alfalfa varieties offer potential quality gains. Hay & Forage Grower. https://hayandforage.com/

2Wiersma, R.W. and Wiederholt, R. Alfalfa cutting height to maximize forage yield and quality. https://fyi.uwex.edu.

3Holmes, B. Dry round hay bale storage costs. https://fyi.uwex.edu. Web sources verified 8/30/20. 7010_S1